Discussion

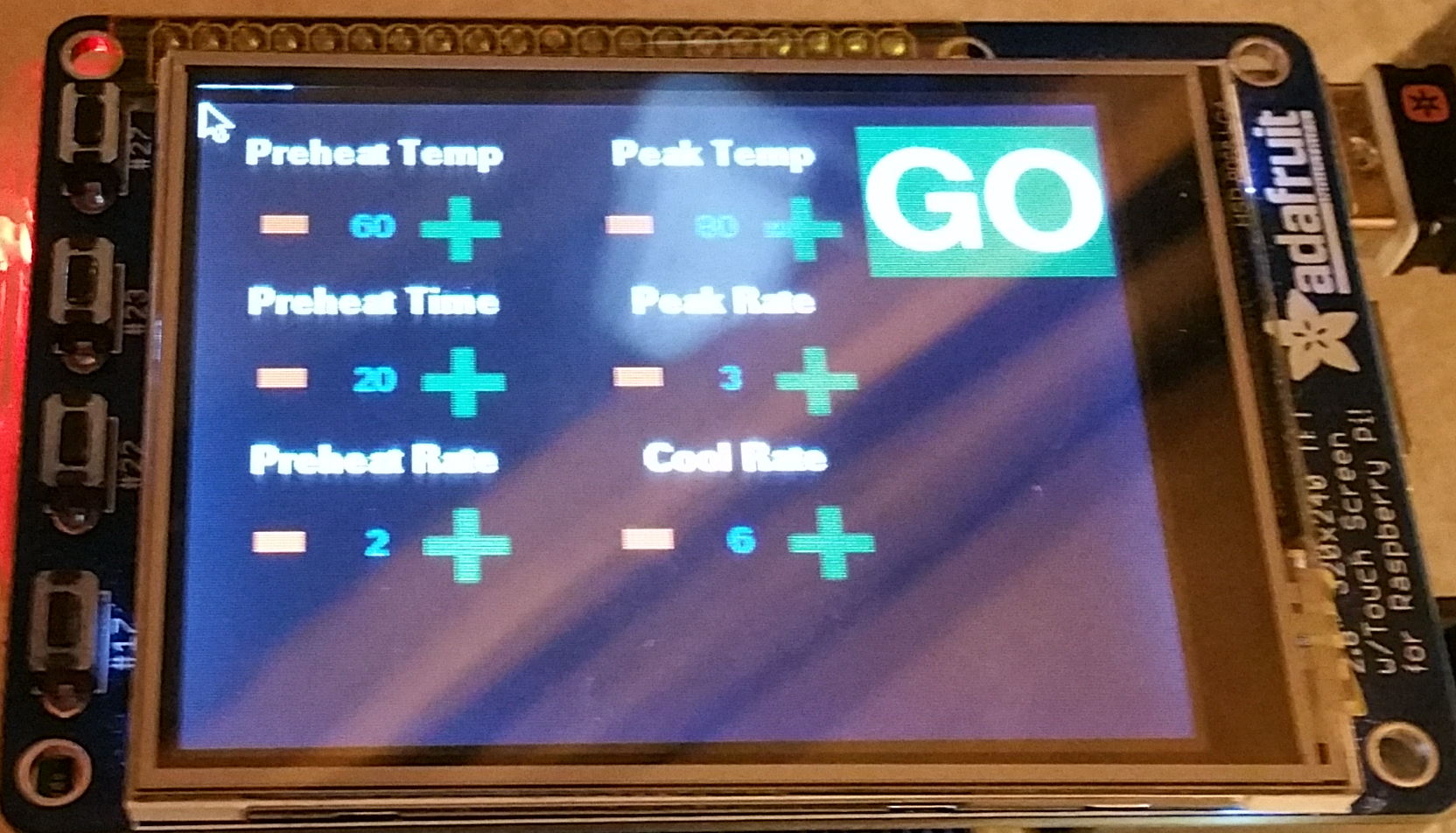

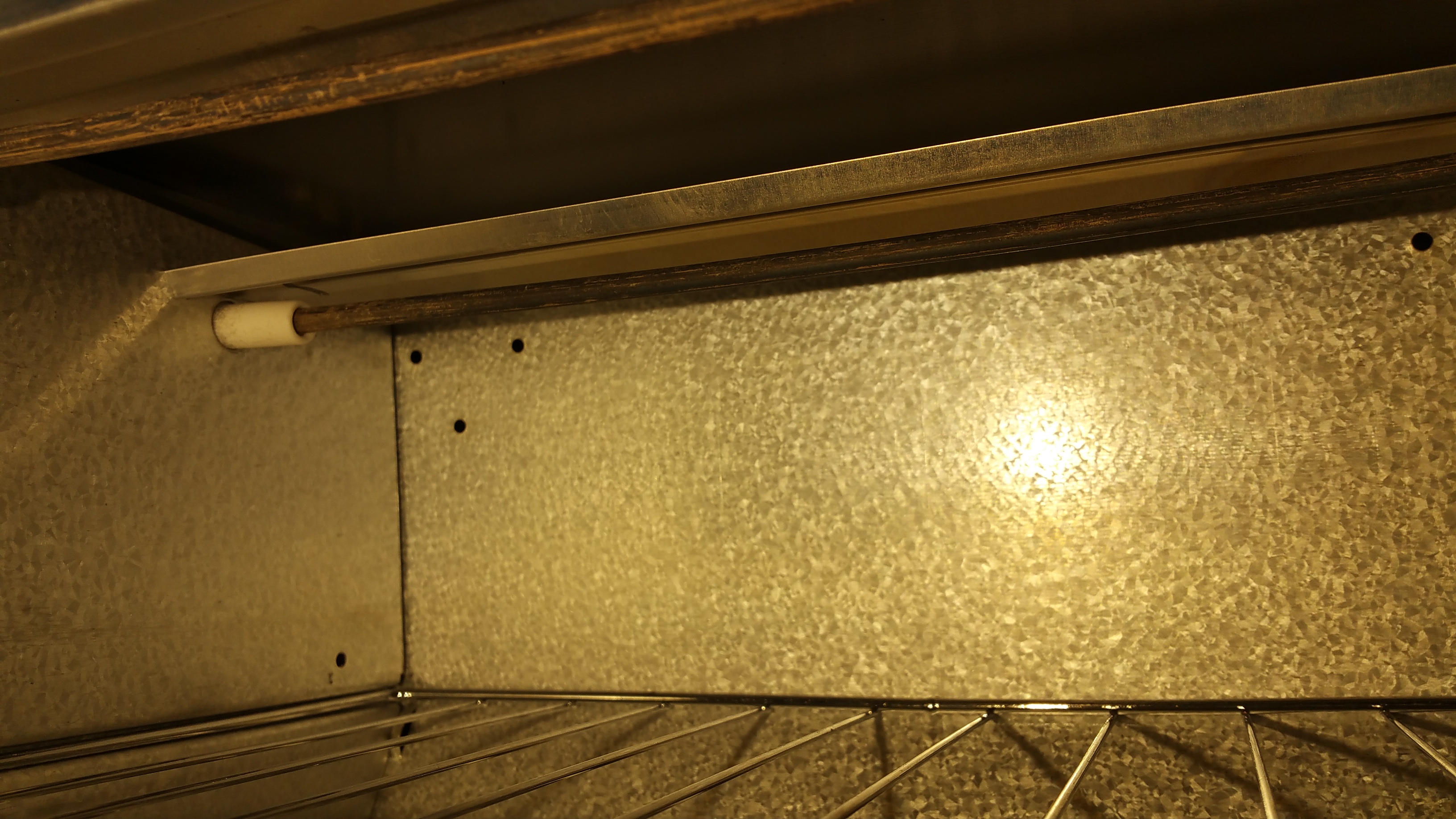

The "PID" controller was almost overkill for this project. Due to the lack-luster heat up time of the heating elements, the PID controller barely had any time to respond to changes in temperature. This resulted in a temperature profile that had one continuous increase in temperature until it reached the peak reflow temperature. This is not a huge problem as surface mount packages are still able to be reflowed properly using the oven. In more precise and accurate applications of reflow oven usage, this would result in failure. Thankfully though, ReflowberryPi is expected to be used in a not so strict working environment. In concurrency to this isssue, the cooling process is also slow. Any attempts at touching or moving the board after reflowing is quite futile as burns and other painful side affects will occur.

Conclusion

Overall, this final lab allowed us to really express ourselves and find a cool project that we felt would be applicable in our lives. We both expect to use the oven heavily throughout the last year at Cornell and expect others in our project team to utilize the oven as well. The lab went mostly as expected with a few bumps in the road. One being the door automation issue and the other being the heating issue and how to handle things at higher temperatures (ie you can't just use duct tape). The lab felt as if it was the final culminating design project it was meant to be. All elements from previous labs had a big impact on the way we handle this deisgn project.